Workforce productivity, flexibility, and safety are cited as key gains from AI applications. It also holds promise in tackling the industrial skills shortage.

Honeywell (Nasdaq: HON) has released the findings of its Industrial AI Insights global research. The study captures the current state of Artificial Intelligence in the sector.

Only 17% of AI decision makers have fully implemented initial plans. However, over 90% are discovering new use cases during prototype, launch, or scaling phases.

AI leaders are clearly convinced of its value. About 94% plan to expand their use of AI across more industrial processes and business units.

“There is no question that AI is currently at a pivotal moment,” said Kevin Dehoff, Chief Strategy Officer at Honeywell.

“With Gen AI and data from advanced analytics, Industrial AI is set to grow exponentially. The possibilities for revenue growth and satisfaction are endless.”

AI Unlocks Workplace Benefits

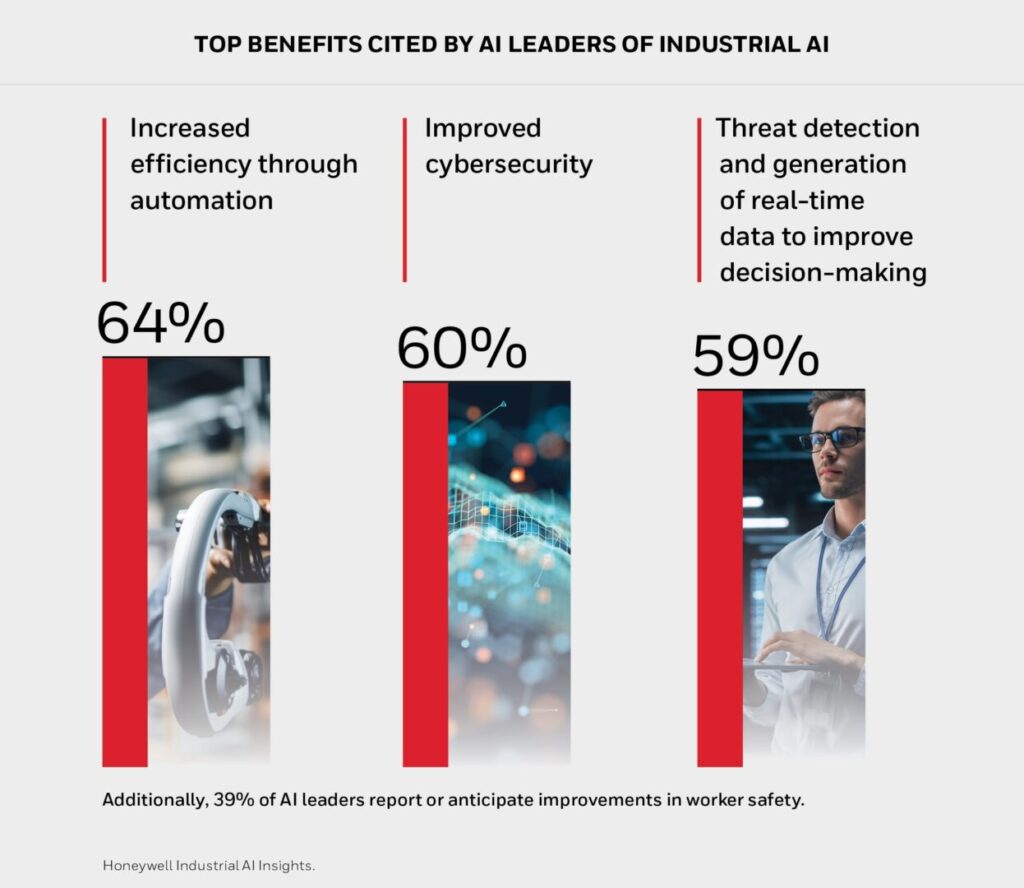

When asked for their thoughts on the impact of AI on industrials, nearly two-thirds (64%) of AI leaders cited efficiency and productivity gains among the most promising benefits. Sixty percent say improved cybersecurity and threat detection result from AI and 59% report better decision making due to real-time data generation.

Several other benefits of AI for workers were also cited by respondents, including:

- Increased work flexibility (49%)

- Greater job satisfaction (45%)

- More time for skills development and creative thinking (44%)

- Increased workplace safety (39%)

Skills development is crucial in today’s economy with baby boomers retiring and fewer replacements entering the workforce. Through AI, employers can more quickly upskill and reskill workers. AI will transform industrials as it enables workers to perform jobs at higher levels, providing greater job satisfaction while increasing productivity and addressing the skills shortage.

Lucian Boldea, President and CEO of Honeywell Industrial Automation offered one direct example: “There can be tens of thousands of instruments, equipment, and valves needed to process and manufacture a product and many of the parts we supply manufacturers require highly experienced technicians for operation and maintenance – and there are fewer and fewer of those experienced technicians available. With AI training and AI as a “co-pilot,” the skills of less-experienced technicians can be upgraded more quickly, turning them into more elite experts who perform tasks based on enterprise knowledge and best practices. In turn, plants’ operations can run more safely and reliably by dramatically reducing human error.”

What’s Next for AI

While the enthusiasm for AI to expand is palpable, there are still some challenges in the way of full adoption. More than a third of survey respondents (37%) feel that their C-Suite fully doesn’t understand how AI works and almost half (48%) say they are having to continually justify or request resources needed to implement AI plans.

“Businesses of all types recognize that AI is transforming our world and creating new possibilities. For building operations – such as hospitals, campuses, and offices – it is clearly the future. As AI orchestrates controls that regulate HVAC, lighting and electricity usage, it helps to improve safety, operational and sustainability outcomes,” said Billal Hammoud, President and CEO of Honeywell Building Automation.

All of this suggests the pace of change will be driven by compelling use cases that can be measured in terms of improved business performance. As new solutions demonstrate clear benefits to workforce productivity, safety, and reliability, AI adoption will dramatically increase with the potential to transform industrial operations.