OTC 2025: Blue BMS What We Discovered

By Blue BMS | Category: Offshore Technology

Introduction: Why We Attended OTC 2025 (Even Without a Booth)

The buzz in the halls of this year’s premier offshore technology event was deafening. The OTC 2025 (Offshore Technology Conference) has closed its doors, once again solidifying its status as the global epicenter for discussions on the future of energy. The dominant themes? Decarbonization, accelerated digitalization, AI, and relentless operational efficiency.

For many companies, the goal was to exhibit at grand booths. For the specialist team at Blue BMS, our mission was different: to listen, analyze, and validate.

We didn’t go to present; we went to diagnose…

💡 Key Insights from Blue BMS (Post-OTC 2025)

- The End of Silos is Real: Integration is now mandatory for safety systems.

- Predictive, Not Reactive: Maintenance strategies must anticipate failures.

- BMS as a Decarbonization Tool: Energy optimization drives ESG results.

- Compliance Automation: Data-driven BMS platforms simplify audits.

Trend 1: The Announced Death of Silos (The End of Isolated Fire Safety)

At OTC 2025, the most frequent and emotional conversation wasn’t about the next AI buzzword or a specific new technology — it was about the growing frustration with disconnected systems.

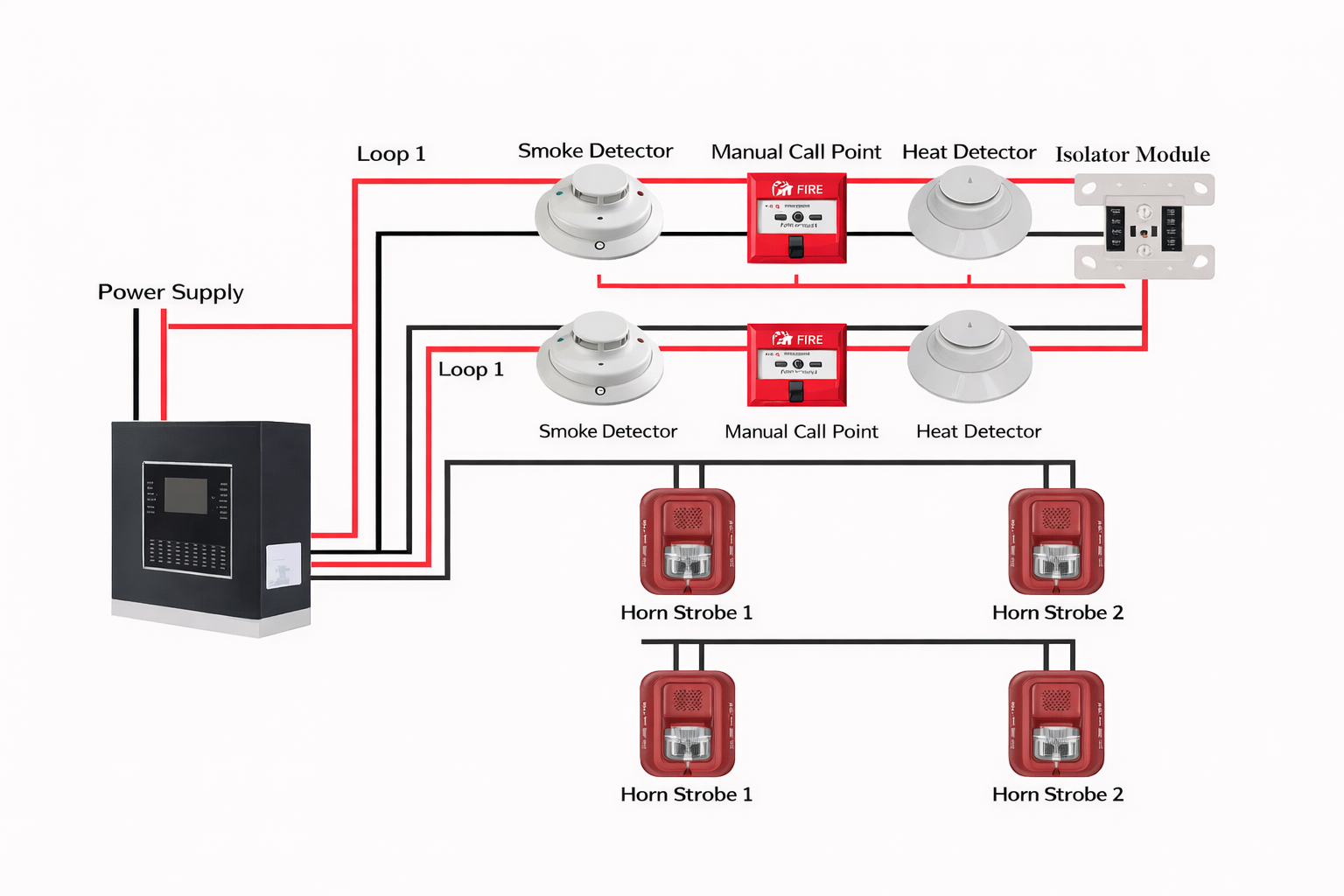

Across every panel and technical session, one message echoed: the era of isolated fire and safety systems is over. Offshore facilities, especially platforms and FPSOs, still operate legacy setups where fire alarms, gas detection, HVAC, access control, and CCTV function as separate, stand-alone silos.

This fragmentation doesn’t just create inefficiency — it introduces critical safety risks. When alarms don’t “talk” to each other, precious seconds are lost in emergencies. Modern operators now see system isolation as a direct threat to human safety and operational continuity.

Deep Dive: The Risk Scenario in Practice

Imagine a small methane (CH₄) leak detected by a gas sensor in a process module.

-

In a siloed system, the detector triggers a local alarm. The control room operator notices the signal, then manually contacts the HVAC team to shut down ventilation. During that delay, gas spreads through ducts, raising the risk of ignition.

-

In an integrated BMS environment, the same alarm automatically triggers a coordinated response: ventilation shuts down instantly, dampers close, escape routes unlock, and the nearest CCTV feed pops up on the operator’s screen — all within milliseconds.

That’s not futuristic — it’s the new operational expectation. Integration has evolved from a technical luxury to a regulatory and ethical necessity. As one offshore HSE director put it during OTC 2025: “If our fire safety doesn’t communicate across systems, it’s not safety — it’s just a set of alarms.”

Trend 2: The Quantum Leap – From Reactive to Predictive

If integration was the dominant theme at OTC 2025, prediction was the next frontier.

The industry’s largest hidden cost is not equipment or manpower — it’s unplanned downtime.

Every hour that a production system is offline due to equipment failure can represent millions in losses. And yet, most safety and facility systems still rely on calendar-based maintenance — testing a fire pump every 90 days or inspecting smoke detectors once a year.

The problem? Risk doesn’t follow a calendar.

A pump can corrode in weeks under saline conditions. A sensor can degrade overnight after a surge. The industry consensus emerging from OTC 2025 was clear: the future is predictive, not reactive.

The Hidden Risk of “It’s Working”

A system that “worked during last inspection” doesn’t guarantee it will work tomorrow. Corrosion, vibration, and environmental stress degrade offshore assets continuously. The old model only confirms that the system functioned in the past.

With advanced data analytics and sensor connectivity, modern BMS platforms can now monitor the health of critical assets in real time — tracking parameters such as vibration, current draw, and temperature.

When deviations occur, the BMS doesn’t just alert — it predicts.

It can generate actionable insights like:

“Warning: Fire Pump B-01 shows a 78% probability of bearing failure within 21 days.”

This approach allows maintenance teams to act before failure, reducing downtime to near zero while ensuring compliance with SOLAS and class requirements.

Predictive maintenance is no longer a futuristic concept — it’s the new foundation of safety assurance in offshore operations.

Trend 3: Energy Efficiency is the New Currency (ESG, Cost, and the Role of BMS)

Decarbonization and ESG were dominant themes at OTC 2025. But while many discussions focused on carbon capture and green fuels, another major emission source often went unnoticed: the energy consumption of offshore platforms themselves.

An offshore platform is essentially a floating city powered by diesel or gas turbines. And after production systems, the HVAC system is typically the largest single consumer of energy — responsible for 25–40% of onboard power usage.

The Hidden Cost of Offshore HVAC

HVAC systems run 24/7 to maintain safe temperatures and air quality. But many operate on static schedules and outdated controls, wasting enormous energy.

A smart BMS changes this equation.

By using real-time data from temperature, occupancy, and CO₂ sensors, the BMS dynamically adjusts airflow, cooling, and pressure balance. This alone can cut energy consumption by 15–30%.

In financial terms, that translates to hundreds of thousands of dollars in annual fuel savings — and directly supports corporate ESG targets by reducing CO₂ emissions.

During OTC 2025, several operators noted that “energy efficiency has become a profit center, not just an ESG checkbox.”

The message is clear: the BMS is now a decarbonization tool, linking environmental responsibility to operational performance.

Trend 4: The Global Compliance Challenge (From Burden to Asset)

No matter where you operate — North Sea, Gulf of Mexico, or Asia-Pacific — compliance frameworks like SOLAS, MODU Code, DNV, ABS, and ISO demand relentless documentation and audit readiness.

The problem? Compliance has become a full-time administrative burden.

HSE teams spend weeks compiling spreadsheets and reports to prove adherence to testing schedules, emergency response times, and equipment inspections.

At OTC 2025, one clear trend emerged: compliance automation.

A modern BMS can act as an unalterable “black box” that automatically logs every safety event, maintenance action, and sensor test.

-

Did the deluge pump test execute on schedule? ✅ Logged.

-

Was the gas alarm acknowledged within the required response window? ✅ Logged.

-

Did the predictive maintenance alert trigger a work order under ISO 55000 guidelines? ✅ Logged.

When auditors arrive, managers no longer scramble for evidence — they export a ready-made report directly from the BMS dashboard.

The result: compliance transforms from a reactive burden into a proactive operational advantage.

Conclusion: Our Post-OTC 2025 Vision

Blue BMS left OTC 2025 with a strengthened conviction: the offshore industry doesn’t need more tools — it needs smarter connections.

Technology for technology’s sake adds noise. What moves the industry forward is integration that saves seconds, predicts failures, and ensures compliance automatically.

The future of offshore safety and efficiency lies in intelligent ecosystems, where Fire Safety, HVAC, access control, and maintenance converge under one predictive, data-driven platform.

As we look beyond OTC 2025, one message stands firm:

The goal isn’t to collect more data — it’s to extract real wisdom from the data you already have.

And that’s exactly where Blue BMS continues to lead — turning information into intelligence, and intelligence into safety.

Frequently Asked Questions (FAQ)

Q: Why did Blue BMS visit OTC 2025 instead of exhibiting?

A: Our goal was listening and validation. We sat with operators to understand emerging offshore challenges…

Q: What’s the biggest Fire Safety trend post-OTC 2025?

A: Total integration and predictive maintenance. Fire alarms, HVAC, and access systems must act as one…

Q: How does BMS help decarbonization?

A: Smart BMS optimizes HVAC loads, reducing diesel-based energy consumption and CO₂ emissions…

Q: How is an offshore BMS different from a commercial one?

A: Offshore BMS operates in extreme conditions and integrates with safety-critical systems (H₂S, deluge, CO₂ suppression)…

Is your offshore operation still managing isolated systems?

What we saw at OTC 2025 is clear: efficiency and safety depend on integration. Start your predictive transformation today.

Click Here to Schedule a Systems Integration Maturity Analysis