Mastering Fire Safety: How Dry Chemical Suppression Systems Protect Your Business

In today’s fast-paced business environment, the protection of assets and personnel is paramount, making fire safety more critical than ever. Fire incidents can disrupt operations and lead to financial and emotional devastating losses. Fortunately, mastering fire safety is achievable through effective solutions like dry chemical suppression systems. These advanced systems are designed to combat various types of fires, minimizing damage and ensuring rapid emergency response. Understanding how these mechanisms work and their benefits can significantly enhance your safety strategy. In this article, we will explore the vital role dry chemical suppression systems play in fire safety, highlighting their unique features and advantages tailored for businesses. From installation to maintenance, we’ll provide insights that empower you to safeguard your operations, keeping your workforce and valuables out of harm’s way. Join us as we delve into the essentials of optimizing fire safety within your organization and ensuring peace of mind in the face of potential threats.

Understanding Fire Safety in Commercial Settings

Fire safety in commercial settings is a multifaceted endeavor that requires meticulous planning and implementation. Businesses face various fire-related risks due to the nature of their operations, the materials they handle, and the environments in which they operate. Each commercial setting, whether it’s a bustling office, a factory filled with machinery, or a retail store, demands a tailored approach to fire safety to ensure maximum protection of both people and assets. Recognizing these unique needs is the first step towards developing an effective fire safety strategy.

One of the primary considerations in fire safety is understanding the types of fire that can occur. Fires are categorized into different classes based on the materials involved. For example, Class A fires involve ordinary combustibles like wood and paper, Class B fires involve flammable liquids, and Class C fires involve electrical equipment. Each type of fire requires a specific suppression method for effective control. Therefore, businesses must assess their specific fire risks and ensure they have the appropriate suppression systems in place.

Moreover, fire safety in commercial settings is not just about having the right equipment; it also involves educating employees and conducting regular fire drills. Employees should be trained in fire prevention measures, the proper use of fire extinguishers, and the protocols to follow during an emergency. Regular drills help ensure that everyone knows their roles and can act swiftly and calmly in the event of a fire. Combining advanced suppression systems with well-trained personnel creates a robust fire safety environment that can significantly mitigate risks.

What are Dry Chemical Suppression Systems?

Dry chemical suppression systems are a critical component of modern fire safety strategies. These systems use specially formulated powders to suppress fires quickly and effectively. The dry chemical agents are capable of extinguishing various types of fires, making them highly versatile and suitable for diverse commercial settings. The most commonly used dry chemicals include monoammonium phosphate, sodium bicarbonate, and potassium bicarbonate, each selected based on its effectiveness against specific fire classes.

The primary function of dry chemical suppression systems is to interrupt the chemical reaction that sustains a fire. When a fire breaks out, the system releases a cloud of dry chemical powder over the affected area. The powder forms a barrier between the fuel and the oxygen in the air, effectively smothering the flames and preventing re-ignition. This rapid response is crucial in minimizing damage and ensuring the safety of occupants.

Furthermore, dry chemical suppression systems are designed to be both automatic and manual. Automatic systems are equipped with sensors that detect heat, smoke, or flames and activate the suppression system without human intervention. Manual systems, on the other hand, require an individual to trigger the release of the dry chemical agent. The combination of these features ensures that fires can be addressed promptly, regardless of whether the building is occupied or not.

How Dry Chemical Suppression Systems Work

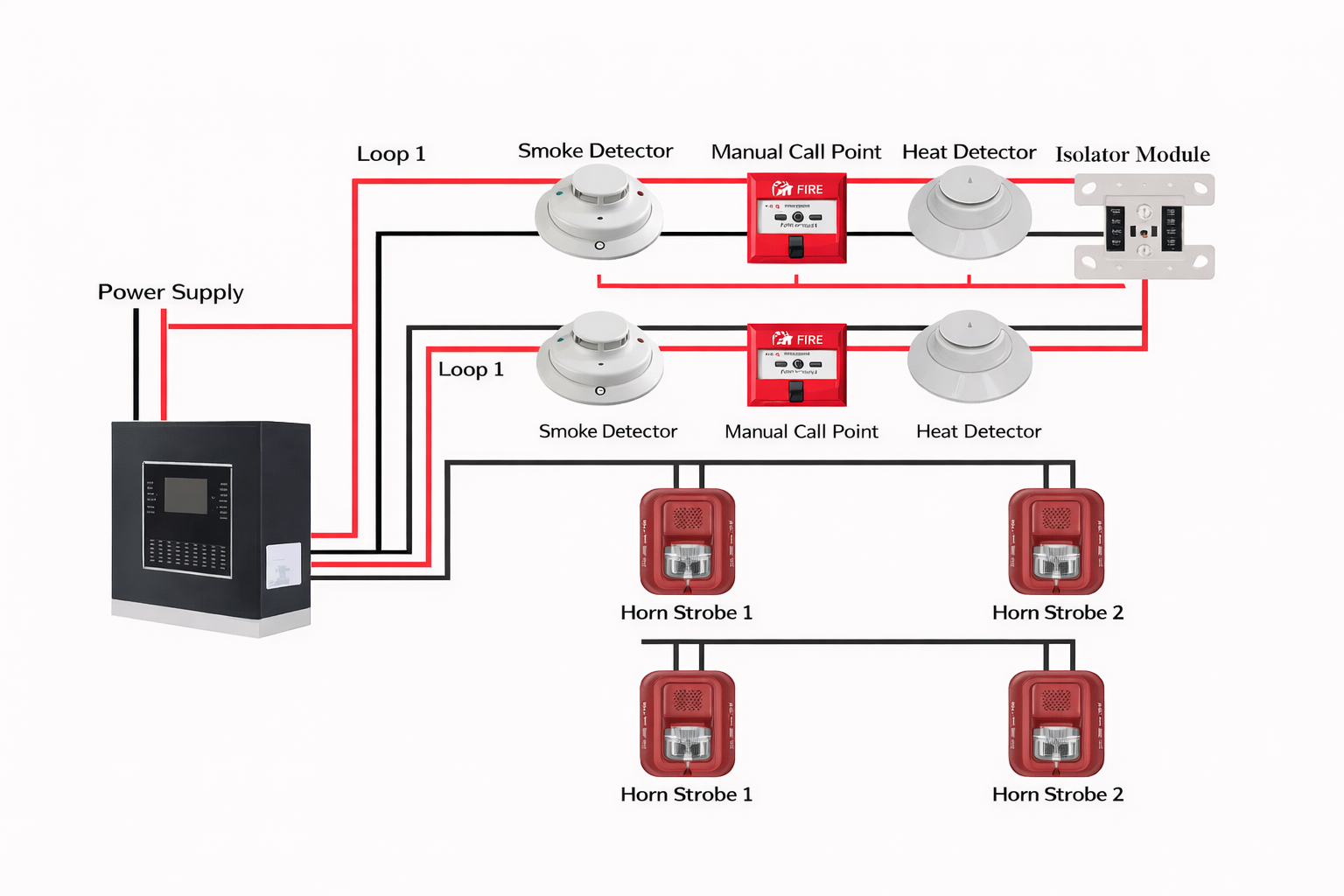

The operation of dry chemical suppression systems involves several key components working in unison to detect and suppress fires. At the heart of these systems are the detection mechanisms, which can include heat detectors, smoke detectors, and flame detectors. These sensors continuously monitor the environment for signs of a fire. When a fire is detected, the system’s control panel receives a signal and initiates the suppression process.

Once activated, the system releases the dry chemical agent through a network of pipes and nozzles strategically placed throughout the protected area. The dry chemical powder is stored in pressurized containers, ensuring it can be deployed rapidly and effectively. The nozzles are designed to disperse the powder evenly, covering the fire with a blanket of chemical agent that interrupts the combustion process. This rapid deployment is essential in preventing the fire from spreading and causing further damage.

An important aspect of dry chemical suppression systems is their ability to be tailored to specific environments. The concentration and type of dry chemical agent can be adjusted based on the fire risks present in a particular setting. For example, in a kitchen environment where grease fires are a concern, a different type of dry chemical agent may be used compared to an industrial setting with electrical equipment. This flexibility ensures that the suppression system is optimized for maximum effectiveness.

Benefits of Implementing Dry Chemical Suppression Systems

Implementing dry chemical suppression systems offers numerous benefits that make them an attractive option for businesses seeking comprehensive fire protection. One of the most significant advantages is their effectiveness in suppressing a wide range of fire types. The versatility of dry chemical agents allows these systems to combat Class A, B, and C fires, making them suitable for various commercial and industrial applications. This multi-purpose capability ensures that businesses are well-protected against diverse fire hazards.

Another key benefit is the rapid response time of dry chemical suppression systems. These systems are designed to detect and suppress fires swiftly, often within seconds of detection. This quick action is crucial in minimizing property damage and reducing downtime. In many cases, the prompt suppression of a fire can prevent it from escalating to a point where it causes significant structural damage or disrupts operations for an extended period. This not only protects assets but also ensures business continuity.

Moreover, dry chemical suppression systems are relatively easy to install and maintain. The components are modular and can be integrated into existing fire safety infrastructure with minimal disruption. Routine maintenance typically involves regular inspections, testing of sensors and control panels, and replenishment of the dry chemical agents. This straightforward maintenance process helps ensure that the system remains in optimal working condition, ready to respond to any fire emergency. Additionally, the cost-effectiveness of these systems makes them an attractive investment for businesses looking to enhance their fire safety measures without incurring prohibitive expenses.

Key Industries That Benefit from Dry Chemical Suppression

Several industries can significantly benefit from the implementation of dry chemical suppression systems due to their specific fire risks and operational environments. The manufacturing industry, for instance, often involves the use of flammable materials, heavy machinery, and complex electrical systems. Dry chemical suppression systems are ideal for these settings as they can quickly suppress fires involving combustible materials and electrical equipment, minimizing potential damage and ensuring the safety of workers.

The hospitality industry, including hotels and restaurants, also greatly benefits from dry chemical suppression systems. In these environments, kitchen fires are a common risk due to the presence of cooking oils and open flames. Dry chemical agents are effective in suppressing grease fires, which are notoriously difficult to extinguish with water. By implementing these systems, hospitality businesses can protect their guests and staff, ensuring a safe and secure environment.

The technology sector, particularly data centers and server rooms, is another industry where dry chemical suppression systems are invaluable. These environments house sensitive electronic equipment that can be severely damaged by fire. Dry chemical agents are non-conductive and can safely suppress electrical fires without causing harm to the equipment. This protection is crucial in preventing data loss and maintaining the integrity of critical infrastructure. Other industries, such as healthcare, retail, and transportation, also benefit from the versatility and effectiveness of dry chemical suppression systems, making them a vital component of comprehensive fire safety strategies.

Compliance and Regulations for Fire Safety Systems

Compliance with fire safety regulations is a critical aspect of maintaining a safe and legally compliant business environment. Various regulatory bodies, such as the National Fire Protection Association (NFPA) in the United States, establish standards and guidelines for the design, installation, and maintenance of fire suppression systems. These standards ensure that fire safety systems are effective and reliable, providing businesses with a framework to achieve optimal fire protection.

One of the key regulations concerning dry chemical suppression systems is NFPA 17, which outlines the requirements for the installation and maintenance of dry chemical extinguishing systems. This standard covers aspects such as the types of dry chemical agents that can be used, the design of the distribution system, and the necessary testing and inspection procedures. Adhering to NFPA 17 ensures that the suppression system is capable of effectively controlling fires and meets the necessary safety criteria.

Additionally, businesses must be aware of local fire safety codes and regulations, which may vary depending on the jurisdiction. Local fire departments and building authorities often conduct inspections to ensure compliance with these regulations. Non-compliance can result in fines, legal liabilities, and increased insurance premiums. Therefore, businesses need to stay informed about the relevant fire safety requirements and work with certified professionals to ensure their suppression systems are compliant.

Regular training and education for employees are also mandated by many fire safety regulations. Employees should be familiar with the operation of the fire suppression system, emergency evacuation procedures, and the location of fire exits and equipment. Conducting regular fire drills and safety training sessions helps ensure that employees are prepared to respond appropriately in the event of a fire, further enhancing the overall safety of the workplace.

Installation and Maintenance of Dry Chemical Suppression Systems

The installation of dry chemical suppression systems involves a detailed process that requires careful planning and execution to ensure optimal performance. The first step is a thorough assessment of the fire risks present in the business environment. This assessment helps determine the type and quantity of dry chemical agents needed, as well as the strategic placement of sensors and nozzles. Working with a certified fire protection specialist is crucial during this phase to ensure that the system is designed to meet the specific needs of the business.

Once the design is finalized, the installation process begins with the placement of detection sensors throughout the protected area. These sensors are connected to the control panel, which monitors their readings and triggers the suppression system when a fire is detected. The distribution network, consisting of pipes and nozzles, is then installed to ensure the even dispersal of the dry chemical agent. It is important to conduct thorough testing of the system after installation to verify that all components are functioning correctly and that the system can effectively suppress a fire.

Maintenance of dry chemical suppression systems is an ongoing requirement to ensure their reliability and effectiveness. Regular inspections should be conducted to check for any signs of wear or damage to the system components. The dry chemical agents need to be replenished periodically to maintain the appropriate levels for effective fire suppression. Additionally, the sensors and control panel should be tested regularly to ensure they are responsive and accurate. Keeping detailed records of all maintenance activities is essential for compliance with fire safety regulations and for ensuring the system’s readiness in an emergency.

Comparing Dry Chemical Systems to Other Fire Suppression Methods

When evaluating fire suppression methods, it is important to compare the features and effectiveness of different systems to determine the best fit for a business’s specific needs. Dry chemical suppression systems offer several advantages over other methods, such as water-based, foam, and gas suppression systems. Each of these systems has unique characteristics and applications, making it essential to understand their differences.

Water-based suppression systems, such as sprinklers, are commonly used in many commercial settings. These systems are highly effective for Class A fires involving ordinary combustibles. However, they can cause significant water damage to property and are not suitable for fires involving flammable liquids or electrical equipment. In contrast, dry chemical systems are versatile and effective against Class A, B, and C fires, making them a more comprehensive solution for diverse fire risks.

Foam suppression systems are particularly effective for Class B fires involving flammable liquids. The foam forms a blanket over the liquid, preventing the release of flammable vapors and extinguishing the fire. While foam systems are highly effective for specific applications, they are not as versatile as dry chemical systems, which can handle multiple fire types. Additionally, foam systems require more complex maintenance and can be more expensive to install.

Gas suppression systems, such as those using CO2 or clean agents, are effective for protecting sensitive electronic equipment and enclosed spaces. These systems work by displacing oxygen or interrupting the chemical reaction of the fire, effectively suppressing it without leaving residues. However, gas systems can pose a risk to human safety if not properly managed, as the displacement of oxygen can be hazardous in occupied spaces. Dry chemical systems, on the other hand, are safer for environments where people are present and offer a balance of effectiveness and safety across various fire scenarios.

Case Studies: Success Stories of Dry Chemical Suppression in Action

Real-world examples of dry chemical suppression systems in action highlight their effectiveness and the critical role they play in protecting businesses from fire-related incidents. One notable case involves a manufacturing plant that experienced a fire in its production area. The fire started when a piece of machinery overheated and ignited nearby combustible materials. The dry chemical suppression system detected the fire and activated within seconds, releasing a cloud of dry chemical powder that quickly smothered the flames. The rapid response prevented the fire from spreading to other parts of the plant, minimizing damage and allowing production to resume shortly after the incident.

Another success story comes from Ansul, a commercial kitchen in a busy restaurant. During peak hours, a grease fire erupted in the kitchen, threatening to spread rapidly. The dry chemical suppression system installed in the cooking area detected the fire and deployed the dry chemical agent, effectively extinguishing the flames before they could cause significant damage. The restaurant staff were able to evacuate safely, and the kitchen was back in operation after a thorough cleanup. This incident underscored the importance of having a reliable fire suppression system in environments where high fire risks are present.

A third example involves a data center that houses critical IT infrastructure. A fire broke out due to an electrical fault in one of the server racks. The dry chemical suppression system detected the fire and activated immediately, releasing the non-conductive dry chemical agent that quickly suppressed the flames without damaging the sensitive electronic equipment. The prompt action of the suppression system prevented data loss and ensured the continuity of operations. This case study demonstrates the suitability of dry chemical systems for protecting valuable and sensitive assets in technology-driven environments.

Conclusion: Ensuring a Safe Business Environment with the Right Fire Safety Measures

In conclusion, mastering fire safety is an essential aspect of protecting your business, employees, and assets. Dry chemical suppression systems offer a versatile and effective solution for combating various types of fires, making them an invaluable component of a comprehensive fire safety strategy. By understanding how these systems work, their benefits, and the industries that can benefit from their implementation, businesses can make informed decisions to enhance their fire protection measures.

Compliance with fire safety regulations and proper installation and maintenance of suppression systems are crucial to ensuring their effectiveness and reliability. By working with certified professionals and staying informed about the latest fire safety standards, businesses can create a safe and compliant environment that minimizes fire risks. Additionally, comparing dry chemical systems to other suppression methods helps identify the most suitable solution for specific fire hazards, ensuring optimal protection.

Ultimately, the successful implementation of dry chemical suppression systems, combined with regular training and preparedness, provides peace of mind and safeguards your operations against potential fire threats. Investing in the right fire safety measures not only protects your business from financial and operational disruptions but also demonstrates a commitment to the safety and well-being of your workforce. By prioritizing fire safety, businesses can thrive in a secure environment, ready to face any challenges that may arise.

Get to know our Dry Chemical Suppression products